Passive Fire Protection

Building elements that can resist fire in order to separate spaces from the enclosure of fire origin do their job merely by being there (i.e. passively) and are, therefore, known as Passive Fire Protection. Passive Fire Protection includes the protection of structural elements to reduce the rate of heat transfer to the structural element.

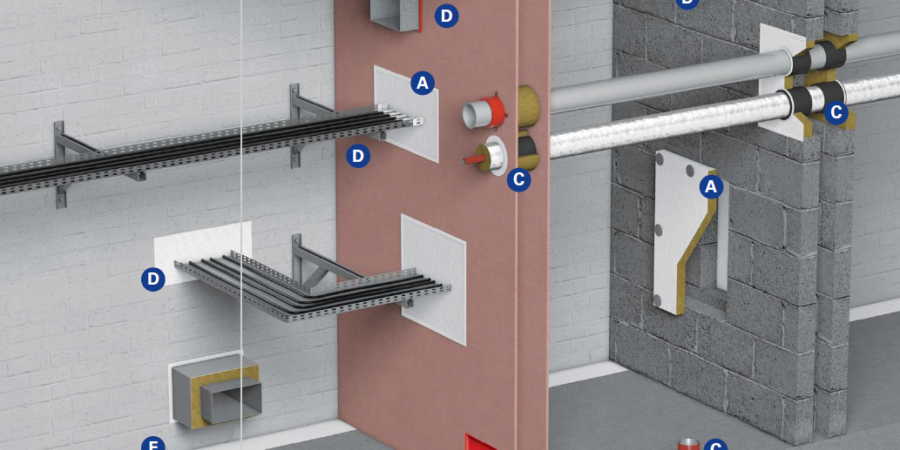

Openings in these building elements must be fire stopped to maintain the ability of the element to prevent the spread of the fire. Due to the large number of combinations of services and substrates these days, selection of the right system can be daunting. Chester can assist you to meet the requirements of Building Consent Authority (for example: Auckland Council position statement for acceptance of fire stopping).

Products such as sealants, mineral wool, fire collars, etc., are available from a variety of suppliers to meet the needs of all fire-stopping instances. Chester uses a database of over 2,200 fire stopping systems tested to standards AS 1530.4 and AS 4072.1 to provide you with design details and test reports to include in your drawings and specifications.

The Passive Fire Protection Process

Retrofits of existing buildings throughout New Zealand, including the refurbishment of leaky buildings, have in recent years uncovered widespread issues with passive fire protection construction. In many cases, the cost of remediation of passive fire protection has increased the cost of projects dramatically and led to only partial remediation. These are known as engineering judgments, a time-consuming and expensive process to obtain Building Consent Authority approval.

For new buildings designers are expected to install systems exactly as tested and therefore must design service routes and riser shafts accordingly. There is no option to install systems “as nearly as reasonably practicable”.

Designers must route their services giving due consideration to the space required to install fire stopping.

This can be achieved by involving Chester at the earliest opportunity for advice on which tested systems are available for the materials they are selecting.

Chester’s approach is to collaborate with the design team from the start of the project through construction to practical completion to provide a firetight building. We believe that constructing a firetight building is a team effort between the contractor, the Building Consent Authority, the architect and the fire engineer.

Concept/Preliminary Design

The passive fire protection design should run concurrently with the building design. We advise the architect on smart location and size of service riser shafts and method of fire stopping. Routes for services can then be defined and followed by the design team. We also will coordinate with the rest of the design team on…Read More

Developed Design

We provide preliminary selections of passive fire protection systems based on the building construction materials and building services design. We have an extensive database of tested products, and manufacturer’s installation specifications to provide options in most cases. We also have good relationships with suppliers to help us find solutions to not-so-common configurations.

Detailed Design

We document the locations of penetrations in fire-rated separations and our solutions, together with detailed manufacturer’s installation specifications, along with the test report justifying the system selection to ensure the design documentation meets the requirements of the Building Consent Authority.

Construction

Resolving passive fire protection detailing on-site is usually a time-consuming and costly exercise and should be avoided, if at all possible. We believe a firetight building is built by a team made up of the contractor, the architect, the building inspector, and the fire engineer. We monitor the construction and installation process against the consented…Read More

Call us to arrange a meeting to discuss your project.

Additional Information

The fire engineering design report is required before passive fire protection can commence. Chester can provide this.

The installation of fire stopping is complex and needs to be carried out by experienced and competent fire-stopping installers. Consideration of competence and availability of installers at the design stage is recommended.

Engaging the fire-stopping installer at the design stage to provide constructability input can reduce costs at the construction stage.

Costs

Passive fire protection design costs will vary with the number of penetrations, different substrates, and different service materials. Installation costs will vary with the number of different suppliers, products, and location of penetrations.

Costs can be reduced by concentrating services to specific points, selecting products from a few suppliers rather than focussing on price per product, selecting simple, easy to install fire-stopping reduces installation costs as well as the future use of the penetration to add or remove services.

Start your project

If you have any questions with your project then fill out the form below and we contact you. We also offer a free 30 minute initial consultation in our office. If you would like to book an appointment then please mention this in the contact form below.